Product description

Adapters, leading rings made from plastics for selflevelling finials marked with TXS symbol are prefabricated elements in class D400 constituting as the upper element of a manhole surface finial that allows to install and assemble a manhole or floating drain (based on the asphalt road surface).

The internal diameters of the TXS adapters are adapted to the insertion of the manhole guide pipe and the necessary connection, structural integration with the manhole. They are located centrally in the top structure on the balancing rings, below the external structural elements of the hatch body, such as hinge pockets, baskets, trusses and supports stiffening the body.

- correct and trouble-free installation (height and diameter relation of the self-levelling manhole body with the manhole’s near-surface finial embedded on and in the asphalt surface);

- protection of the hatch against shifting, horizontal forces during operation;

- resistance to damage when rolling or pressing the hatch into the bituminous surface;

- excellent cooperation of the road surface with the adapter due to high adhesion and similar stiffness of materials;

- protection of the road surface against the negative impact of devices and finials subjected to traffic and environmental loads;

- damping and cushioning of vibrations, elimination of reflected cracks, tightness of the top, stabilization of the road base around the hatch, very good frost and chemical resistance;

- All the above-mentioned functions and advantages make up the high durability, load-bearing capacity and reliability of the manhole top.

- precise foundation of the hatch in the road surface, proper aligning of the hatch surface with the road surface and thus reduction of noise generated by road traffic;

- reduction of the negative impact of road loads on the elements of sewage chambers due to the lack of direct contact between the manhole and the chamber, elimination of the occurrence of point destructive pressures, even distribution of stresses, amortization and damping of communication vibrations;

- higher tightness of the pressed-in hatch in the asphalt pavement and higher low-temperature resistance of the entire structure reduces damage and cracks in the pavement in the vicinity of the self-levelling hatch;

- the surfaces of load-bearing flanges of self-leveling hatches are significantly larger (1800÷2900cm²) than in traditional hatches, thus the direct unit impact of self-levelling hatches on the surface is many times lower, which allows them to be used in heavy and intensive traffic areas.

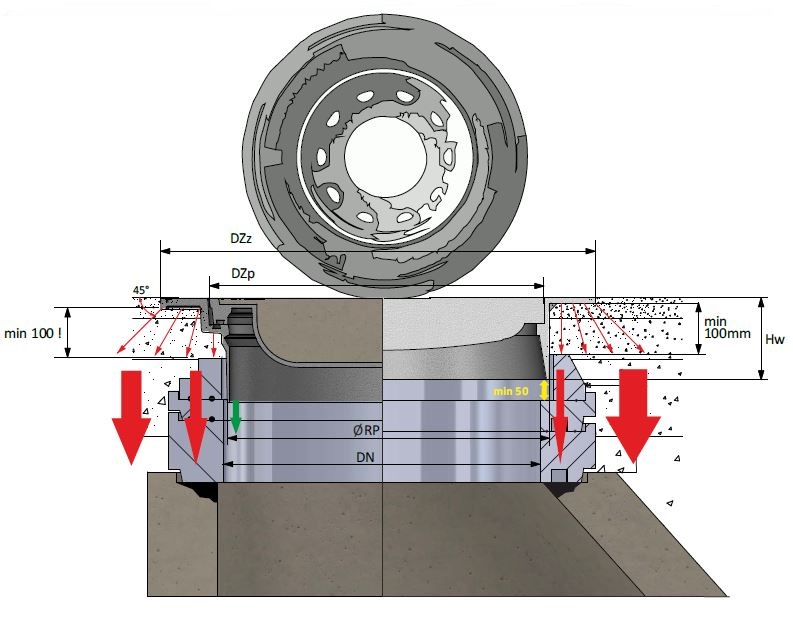

Top of the sewage chamber equipped with a self-leveling manhole

Differences in the transfer of loads generated by road traffic to the elements of the manhole top and the manhole itself result from differences in the construction of self-leveling manholes. The most advantageous solution from the point of view of load distribution and extending the service life is the use of a manhole structure with the largest possible outer diameter of the guide pipe (ØRP 636÷695mm) and a load-bearing flange (DZz 840÷860mm, manhole surface area above 2100cm²). The condition for the correct distribution of loads and transferring them to the road surface and structure is the obligatory maintenance of 10 cm of very well compacted bitumen layer under the load-bearing flange of the manhole. In the case of installing self-leveling manholes whose outer diameter of the ØRP guide pipe is greater than the inner diameter DN of the compensating rings or manhole, it is absolutely necessary to maintain a height of 50mm between the ring / manhole and the lower part of the manhole.